There is a lot of information about the health and safety aspects of solar panel cleaning on social media particularly by well-meaning, but mis-informed people. So ISCA have compiled the ultimate guide to solar panel cleaning personal protective equipement (PPE). The bottom line is that solar panel cleaning is spraying water on to an electricity-creating device, often with a carbon pole in your hand. There is no more perfect recipe for electrocution than we can think of! Wearing the correct PPE is essential.

Exact working at height and electric working risks vary from country to country, no doubt. But whether your country’s health and safety body is OSHA, HSE, Safe Work or another body, the effects of gravity and electricity are the same the world over. Therefore, the PPE elements we discuss for solar panel cleaning are also the same the world over.

There is a common misconception that solar panels can be ‘turned off’. This is one of the great solar panel cleaning myths.

The DC and/or AC isolator switches found near inverters only stop the electricity flow either into the inverter or from the inverter to the property.

Whichever isolator switch one may decide to turn off, does not affect the electricity being created by the solar panels at roof level.

When solar panel cleaning during the daytime, solar panels will always be live and you’ll always be exposing yourself or your staff to the electrocution risk. Therefore, PPE is always needed when cleaning.

How Can Solar Panels Electrocute You Without PPE?

Solar arrays present the risk of shock and electrocution when current takes an unintended path through a human body. Current as low as 75 milliamps (mA) across the heart is lethal. The human body has a resistance of about 600 ohms. Per Ohm’s law, voltage (V) equals current (I) times resistance (R), so V = IR.

To calculate the amount of current that would course through a person’s body if exposed to 120 V, simply divide 120 V by 600 ohms (I = V/R), which totals 0.2 amps or 200 mA. That’s more than 2.5 times the lethal limit of 75 mA, so protecting yourself and your workers against such an event is critical.

Typically, domestic or residential solar arrays can produce up to 600V and commercial systems can produce up to 1,000V. This means that on domestic solar arrays the electrocution risk can be more than 12 times the lethal limit of 75mA and on commercial systems the electrocution risk can be 20 times the lethal limit of 75mA.

If anyone can provide a sound explanation of why they don’t wear PPE when solar panel cleaning, we’d love to hear it!

Solar Panel Cleaning PPE Essentials

Class 0 Gloves

Class 0 gloves are rated to 1000V AC and 1500V DC. Your gloves are your first and main line of defence from electrocution. They will stop any electricity flowing into your body when touching a live frame or when electricity is travelling through your water fed or rotating brush pole.

Class G Hard Hat

Class G hard hats are rated to 2,200V. They are essential when inspecting under solar arrays for signs of damage or bird nesting. Buying a version with a chin strap will stop the helmet from coming off your head when looking under panels or during a fall from height.

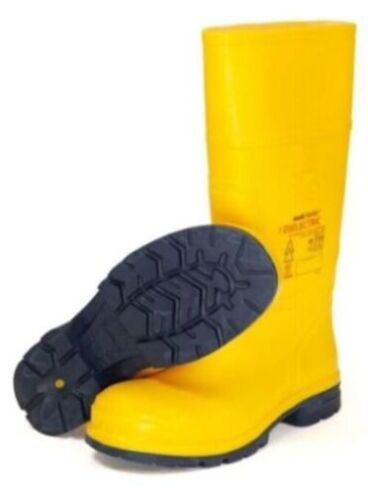

Class 0 Boots

Class 0 dielectric boots are rated to 1kV. They are another essential piece of PPE that protects against electrocution when solar panel cleaning. Cables can have the sheath damaged from birds, rodents or from chafing against sharp edges over time. Stepping on a live DC cable without adequate footwear can result in an electrocution.

Arc Flash Harness

Arc flash harnesses are designed to be worn by workers who work at height and who are exposed to the risk of arc flashes. They are designed to self-extinguish quickly and prevent melting or dripping in the event of an arc flash.

Solar Panel Cleaning PPE Checklist By Cleaning Type

WFP On Ground |

WFP At Height |

Rotating Brush On Ground |

Rotating Brush At Height |

Robot On Ground |

Robot At Height |

|---|---|---|---|---|---|

| Class 0 Gloves | Class 0 Gloves | Class 0 Gloves | Class 0 Gloves | Class 0 Boots | Class 0 Boots |

| Class 0 Boots | Class 0 Boots | Class 0 Boots | Class 0 Boots | Class G Hard Hat | Class G Hard Hat |

| Class G Hard Hat | Class G Hard Hat | Arc Flash Harness | |||

| Arc Flash Harness | Arc Flash Harness |

Conclusion

Solar panel cleaning carries inherent electrocution risks due to the solar panels always being live during daylight hours. Solar panel installers require extensive training and qualifications in order to install solar panels. It is interesting to note that the vast majority of solar installation is completed whilst the systems are dead. The mounting of solar rail to roofs, panels to rails, joining of DC cable and DC connectors together during the installation process are all done when the system is not live. It is not until the last part of a solar installers work, the final connection, that they are dealing with live electricity.

If a solar installer requires training and qualifications to work on dead solar arrays, logic dictates then that solar panel cleaners, who work on permanently live systems, would require training too. ISCA provide solar panel cleaning training which teaches of the electrical hazards associated with the job and how to mitigate them.

We hope that this article encourages solar panel cleaners to start wearing the correct PPE if they do not do so already. For those who need further encouragement, below you will see GRAPHIC images of low voltage injuries from electrocution. We hope that you do not suffer any kind of injury such as those shown below. We encourage all to research solar panel cleaning thoroughly before cleaning solar panels. Please get the relevant training. Please wear your PPE and you will keep you and your staff safe as you go about your work.

Again, we emphasise that the images shown below are not for the fainthearted.

things to know!

Your post on solar panel cleaning brush is incredibly informative and well-written, providing valuable insights and practical tips!

Your article on Solar panel cleaning equipment is exceptionally well-written and insightful, offering a comprehensive understanding of the topic with impressive clarity.

Your detailed post about solar panel cleaning equipment is truly enlightening and showcases your expertise on the topic!