One of the most significant dangers when solar panel cleaning is also hidden. The threat comes from overhead power lines, which pose a deadly threat to those working at heights.

This article delves into the perils associated with cleaning solar panels near overhead power lines. We will also explore the different voltages running through various cables in the USA, UK, South Africa, Australia, and Puerto Rico, and provide guidelines on safe distances to maintain when working near these power lines. We also use other media articles and highlight the hard-hitting example of a solar panel cleaner from California as a cautionary tale.

Understanding the Dangers of Overhead Power Lines

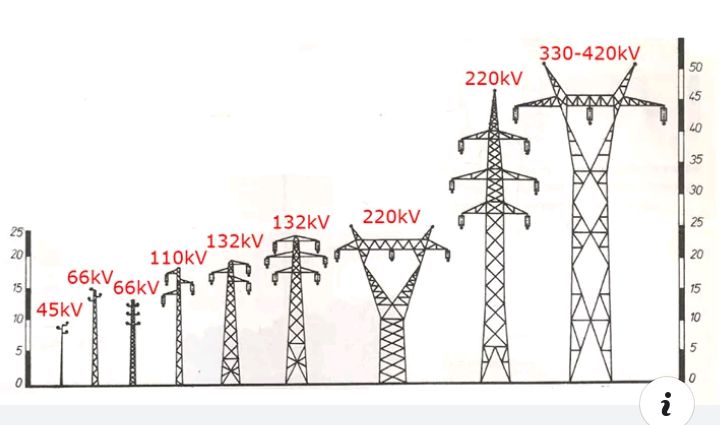

Overhead power lines carry electricity at various voltages, depending on their purpose and location. There are varying designs of powerline types and understanding their design will help you understand their voltages.

When working at heights, such as when cleaning solar panels, the risk of electrocution from these power lines is significant. The dangers are not only from direct contact but also from electrical arcing, where electricity can “jump” from the power line to a nearby conductive object, such as a water-fed pole or a water hose.

The risk is further increased when boom lifts or cherry pickers are used to access roofs. Use of such machines is very common in the solar panel cleaning industry. It is very easy to be concentrating on accessing the roof or navigating your way around a building as you clean solar panels, to the point where you forget to check your distance from overhead power lines.

Training organizations, such as IPAF, provide a lot of safe guidance about working at height near high voltage power lines and it is very worthy of review.

Voltage Levels in Different Countries

- USA

- Residential Distribution Lines: Typically carry 7,200 to 14,400 volts.

- High Voltage Transmission Lines: Range from 69,000 to 500,000 volts.

- UK

- Low Voltage Lines: 230 to 400 volts.

- High Voltage Transmission Lines: Range from 11,000 to 400,000 volts.

- South Africa

- Residential Lines: Generally around 230 to 400 volts.

- High Voltage Lines: Range from 11,000 to 765,000 volts.

- Australia

- Low Voltage Distribution: 230 to 400 volts.

- High Voltage Transmission: 66,000 to 500,000 volts.

- Puerto Rico

- Residential Lines: Usually between 120 to 240 volts.

- High Voltage Lines: Range from 38,000 to 230,000 volts.

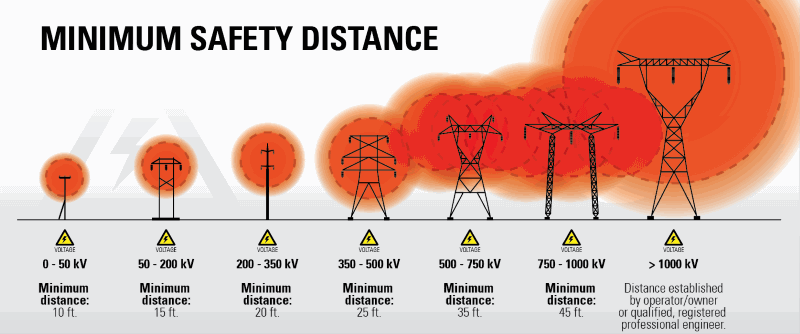

Safe Distances from Overhead Power Lines

The Occupational Safety and Health Administration (OSHA) in the USA provides guidelines on safe distances from power lines, which can be applied universally with slight modifications based on local regulations:

- Up to 50 kV: Maintain at least 10 feet (3 meters) distance.

- 50 kV to 200 kV: Maintain at least 15 feet (4.5 meters) distance.

- 200 kV to 350 kV: Maintain at least 20 feet (6 meters) distance.

- 350 kV to 500 kV: Maintain at least 25 feet (7.5 meters) distance.

- 500 kV to 750 kV: Maintain at least 35 feet (10.5 meters) distance.

- 750 kV to 1000 kV: Maintain at least 45 feet (13.5 meters) distance.

These distances are crucial for preventing accidents and ensuring the safety of workers.

The Dual Threat: Power Lines and Cleaning Equipment

Cleaning solar panels often requires the use of conductive materials like water-fed poles and water hoses, which can exacerbate the risk of electrocution. Even if the equipment does not directly touch a power line, the proximity can be enough for an electrical arc to form. This makes the task doubly dangerous, requiring workers to be vigilant about their surroundings and equipment.

Emphasizing Safety Measures

To mitigate these dangers, it is imperative to follow strict safety protocols:

- Pre-Work Inspection: Always inspect the work site for nearby power lines before beginning any cleaning operations.

- Use Non-Conductive Tools: Whenever possible, use tools made from non-conductive materials such as fiberglass.

- Maintain Safe Distances: Adhere to the recommended safety distances from power lines.

- Training and Awareness: Ensure all workers are trained in electrical safety and are aware of the hazards associated with overhead power lines. Enroll in specialized courses, such as those provided by the International Solar Cleaning Academy (ISCA), which offers comprehensive training on safely cleaning solar panels, including dealing with electrical hazards.

- Safety Gear: Equip workers with proper personal protective equipment (PPE), including insulated gloves and boots. Health and safety regulatory bodies the world over fine heavily anyone who does not provide adequate PPE in the event of an electrical incident. Wearing the correct PPE when solar panel cleaning is not optional. It is essential and potentially lifesaving.

A Real-Life Electrocution Example From California

A few years ago, a solar panel cleaner suffered catastrophic injuries while performing his job. He owned a business specializing in exterior maintenance and was cleaning solar panels in a city near San Francisco. While working on a man lift using a water-fed pole, he accidentally came into contact with a 12,000-volt power line that was exposed, resulting in severe electrocution.

He was knocked unconscious, and the electrical current set his clothes on fire, burning 50 percent of his body.

The man was rushed to the burn center at a nearby medical center, where he resided temporarily. He suffered extensive burns on his back, stomach, arms, and neck, and was placed in a medically induced coma for two weeks. During this time, he underwent eight skin grafting surgeries, fighting for his life.

He faced additional surgeries and physical therapy and remained in the hospital for another six weeks.

The community has rallied around him, raising nearly $40,000 to help with his medical bills through an online support fund. He was denied worker’s compensation since he was self-employed. He has thankfully recovered from the incident and continues to work in the solar O&M industry. This tragic incident serves as a stark reminder of the hazards posed by overhead power lines when cleaning solar panels.

Conclusion

Understanding the voltage levels and maintaining safe distances from overhead powerlines when solar panel cleaning is crucial to preventing such accidents. By adhering to safety protocols and using appropriate equipment, we can protect both ourselves and our staff.

Of equal importance is understanding the voltages running through solar arrays when cleaning them. As long as there is light, there will be current. The inherent electrocution risk is often underestimated by those who clean solar panels.

Safety must always be the priority. Awareness via training and adherence to best practice and safety guidelines can save lives and that above all, should be anyone’s main concern.

Leave A Comment